Other Products

- 合成ダイヤモンドやCBN(立方晶窒化ホウ素)輸入・販売のグローバルダイヤモンド

- English

- PRODUCTS

- Other Products

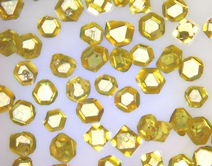

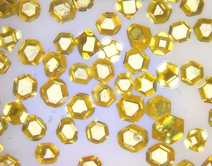

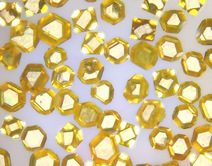

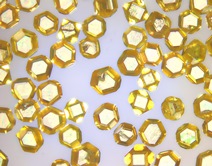

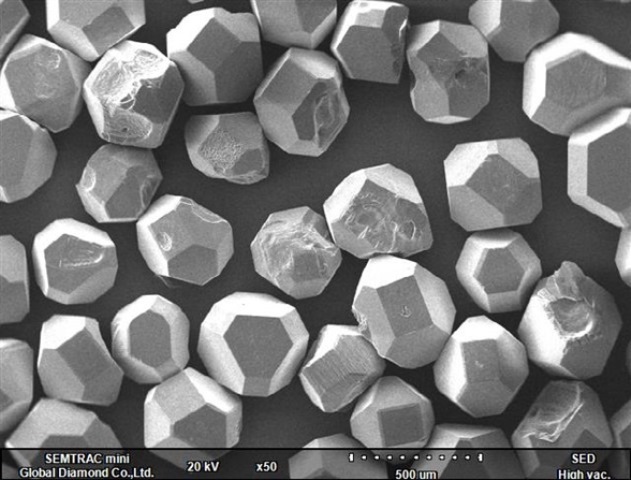

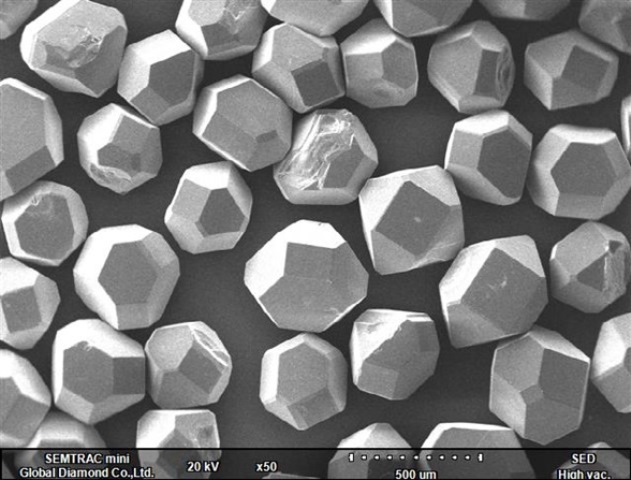

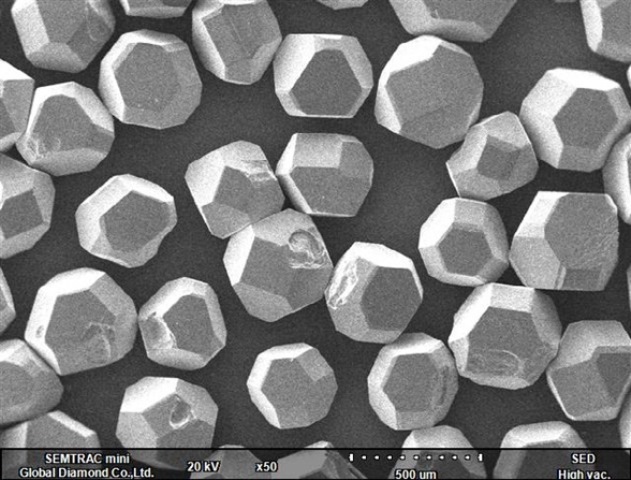

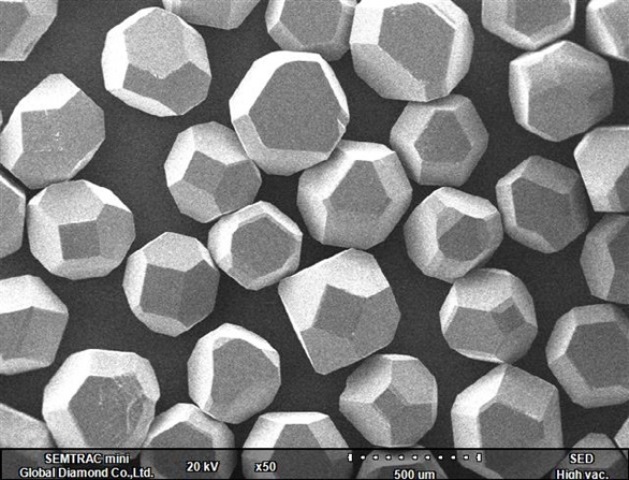

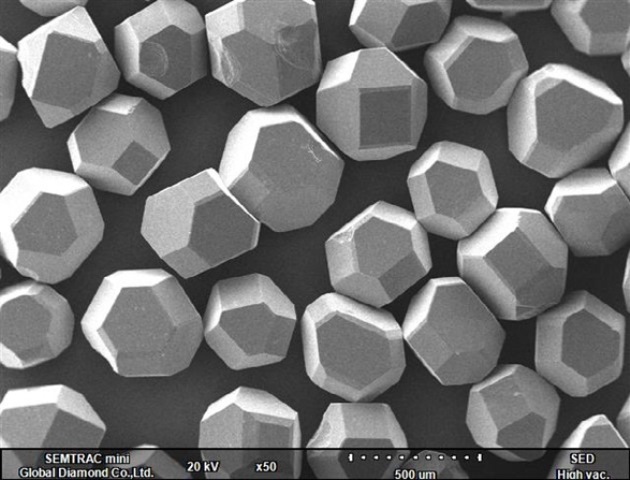

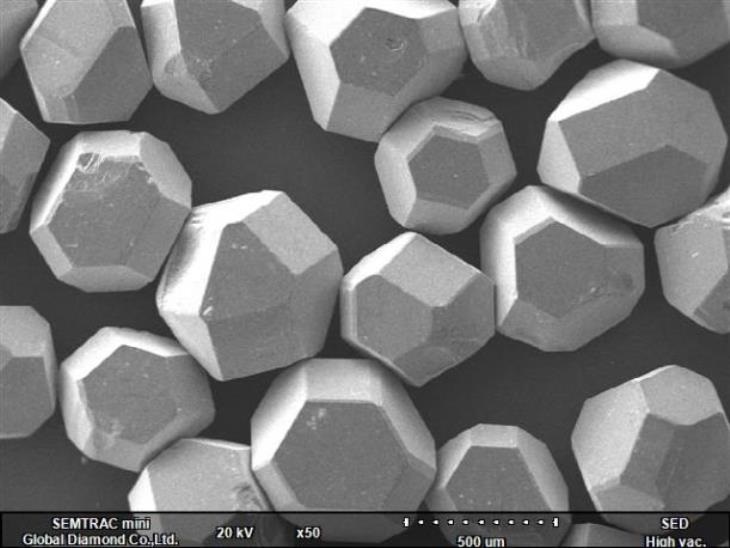

The synthetic diamond powder as a coaser size above #60, is mainly used as a concreat/ stone cutter, therefore it's well known as a "Saw grid diamond".

Also, natural diamond powder for industrial use is introduced after the saw grid.

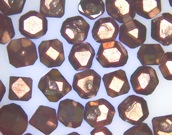

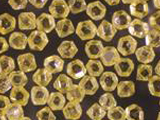

Saw Grid Diamond

ソーサイズ合成ダイヤモンド

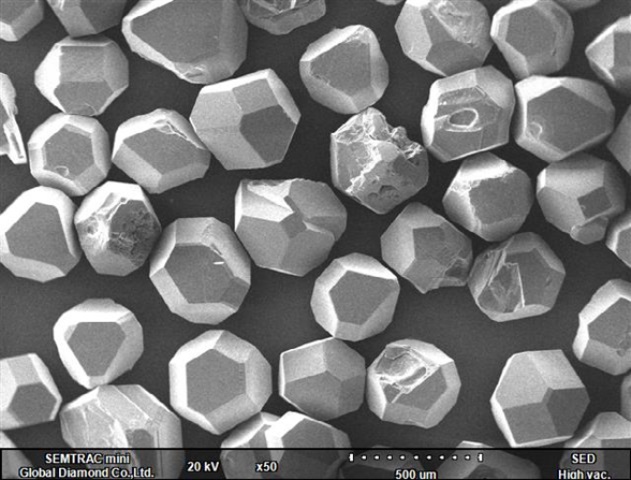

Saw-sized synthetic diamonds are large-grain synthetic diamonds primarily used in tools for processing stone, refractory materials, and civil engineering applications. They are generally yellow in color and have a blocky shape. The fewer the internal impurities and the more solid the crystal, the higher the heat resistance and strength.

We offer a wide lineup of abrasives classified by shape and magnetic sorting, so we can propose the optimal abrasive for your needs.

| GFD20 |

|

| excellent price/performance ratio |

| GFD25 |

|

| low cutting force |

| GFD30 |

|

| wide spectrum of applications and bonding systems |

| GFD40 |

|

| best compromise between material removal rate and tool life |

| GFD60 |

|

| high performance and tool life |

| GFD80 |

|

| higher precision in heavy duty applications |

各種コーティング

coating for synthetic diamond

We offer various surface metal coating and cleaning options to enhance the retention of abrasives on the base material and to reduce the thermal impact on the abrasives.

| GFD80 Ti |

|

| GFD80+Ti Coating |

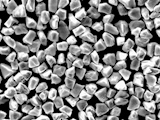

Natural Diamond Powder

天然ダイヤモンドパウダー

Natural diamonds, which do not contain catalysts or metal components used in synthetic diamond production, are characterized by their excellent friability and sharp cutting edges. Due to their low metal content, they can be used as raw materials for electroplated tools, as well as free abrasives.

Although quality control is more challenging for these products compared to synthetic diamonds due to their natural origin, the natural diamonds handled by our company are known for their stable quality, with specific origins identified.

We handle sizes ranging from saw sizes to micron sizes, and some sizes are available from stock.

Size availability

供給サイズ

Saw Grid Diamond

| GFD20 | GFD25 | GFD30 | GFD40 | GFD60 | GFD80 | ||

| 16/18 | △ | △ | △ | △ | △ | 〇 | |

| 16/20 | △ | △ | △ | △ | △ | 〇 | |

| 18/20 | △ | △ | △ | △ | △ | 〇 | |

| 20/30 | △ | △ | 〇 | 〇 | 〇 | 〇 | |

| 25/30 | △ | △ | 〇 | 〇 | 〇 | 〇 | |

| 25/35 | △ | △ | 〇 | 〇 | 〇 | 〇 | |

| 30/35 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 30/40 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 35/40 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 35/45 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 40/45 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 40/50 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 45/50 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 50/60 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 60/80 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 70/80 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| 80/100 | - | 〇 | - | 〇 | - | 〇 | |

| 100/120 | - | 〇 | - | 〇 | - | 〇 | |

| 120/140 | - | 〇 | - | 〇 | - | 〇 | |

| 140/170 | - | 〇 | - | 〇 | - | 〇 | |

| 170/200 | - | 〇 | - | 〇 | - | 〇 | |

| 200/230 | - | 〇 | - | 〇 | - | 〇 | |

| 230/270 | - | 〇 | - | 〇 | - | 〇 | |

| 270/325 | - | 〇 | - | 〇 | - | 〇 | |

| 325/400 | - | 〇 | - | 〇 | - | 〇 | |

| 400/500 | - | 〇 | - | 〇 | - | 〇 | |

Natural Diamond Powder

Saw Size:20/30, 30/40, 40/50

Mesh Size:60/80 ~ 400/500

Micron Size:0-1(D50=about0.5um) ~ 40-60(D50=about45um)