Polycrystalline CVD Diamond

- 合成ダイヤモンドやCBN(立方晶窒化ホウ素)輸入・販売のグローバルダイヤモンド

- English

- PRODUCTS

- Polycrystalline CVD Diamond

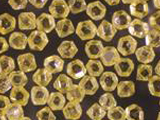

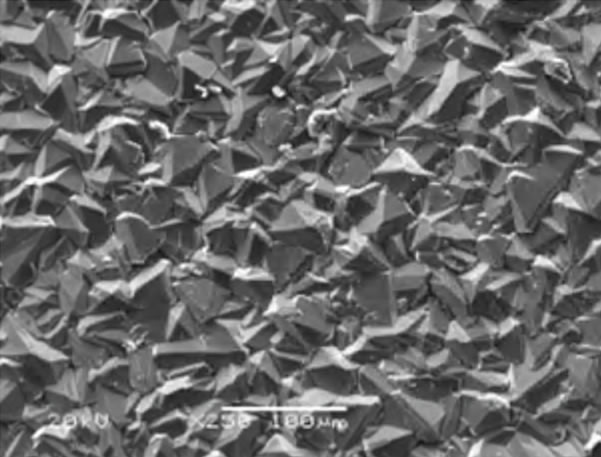

CVD diamonds are synthesized by the chemical vapor deposition method and are mainly manufactured using either the hot filament (thermal excitation) or plasma (discharge excitation) method.

Because it is a 100% carbon diamond without a binder, it excels in the diamond's inherent properties of high hardness, corrosion resistance, wear resistance, electrical insulation, and high thermal conductivity. Additionally, due to its polycrystalline nature, there is no need to consider crystal orientation during use. It can be used for dressers, wire drawing dies, cutting tools, heat dissipation materials (heat sinks), optical lenses, and laser windows.

Polycrystal CVD Diamond "CDK" "CDY"

多結晶CVDダイヤモンド"CDK" "CDY"

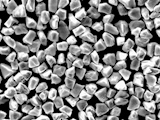

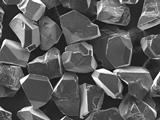

CVD diamonds using the DC plasma method are high-quality and stable products due to an integrated production system from synthesis till polishing, cutting, and cleaning.

We offer two types of grades based on the differences in synthesis growth speed: the standard grade 'CDK' and the premium grade 'CDY.'

横スクロールで全体をご覧いただけます。

| CDY | CDK | |

| Production Method | DC Plasma | DC Plasma |

| Max. Size[Lmm×Dmm×(t)mm] | 10.0×10.0×1.0(t) | 10.0×10.0×1.0(t) |

| Density[×103kg/m3] | 3.51 | 3.51 |

| Thermal Conductivity[W/m・K] | 1,500~2,000 | 800~1,300 |

| CTE [10-6/K] |

~1.0±0.1ppm/k(300k) ~4.4±0.1ppm/k(1000k) |

~1.0±0.1ppm/k(300k) ~4.4±0.1ppm/k(1000k) |

| Electrical Characteristics | Insulation | Insulation |

Size・Shape・Polishing Requirement

サイズ・形状・研磨条件

We can provide various shapes, such as strip, plate, and disk, according to the application. Please feel free to contact us regarding your desired size and growth surface polishing specifications.

CVD Growth Face

Packing Case for Strip shpe(100pcs)